Development skills in passive vehicle safety

Developments in passive safety mean designing vehicles with a maximal reduction of accident consequences for passengers, involved parties and other road users. A high degree of passive safety is achieved through maximum absorption of energy in the chassis, coordinated restraint systems and appropriate design in the interior of the vehicle. In this way, passive safety is an overall function of a vehicle, which is to be achieved through optimal cooperation between all the components involved.

Our strengths

Functional development

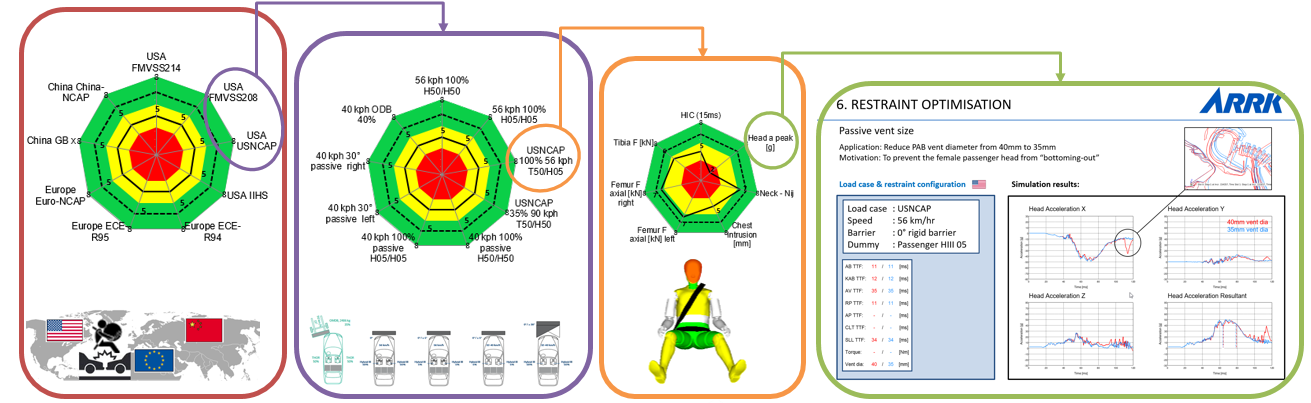

This comprises the optimal adjustment of all components involved and the adaptation of the entire performance to achieve complete product properties. We support you in turning global product targets, such as, for example, a specific consumer protection agency on a specific market, into necessary constituent targets (passive safety).

When it comes to functional development in simulations and tests, we concentrate on the following:

- Total system simulations (all load conditions of passive safety)

- Crash analysis

- Battery casing

- Interior (cockpit, seats, door trim)

- Restraint systems

- Connection technology

Functional levels of passive safety in the development process

Overview functional levels:

1. Global Safety (Active & Passive)

- Market & Approval Strategy

- Vehicle Target Specification (VTS)

- Test- and Prototype Plan

- Homologation

- Consultancy

- NCAP Assessment and Certification

2. Passive Safety Attribute

- Target Breakdown on Sub Systems

- Define Solution Spaces

3. Load Case Evaluation

- Solutions in Systems or Components

- Simulation and Testing

- Monitoring of SS VTS

4. In Depth CAE Analysis

- Function Design

- Engineering

- Supplier Management

- Project Management

We support you with crash simulations of your vehicles - from the first idea to series production.

ARRK Engineering offers support with safety design in:

- Setting product goals

- Specification differentiation

- Interpreting and optimizing target fulfillment

- Technical detail optimization

- Testing carriages and whole systems

- Validation and approval

Conception, virtualization and evaluation:

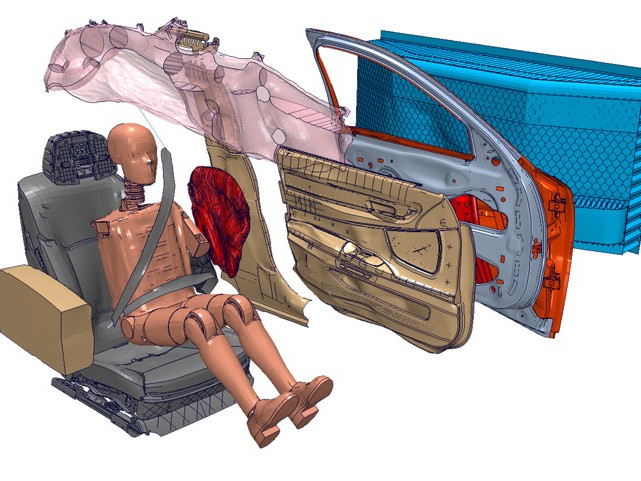

side curtain

Conception, virtualization and evaluation:

SAB (side airbag)

Methods & Tools

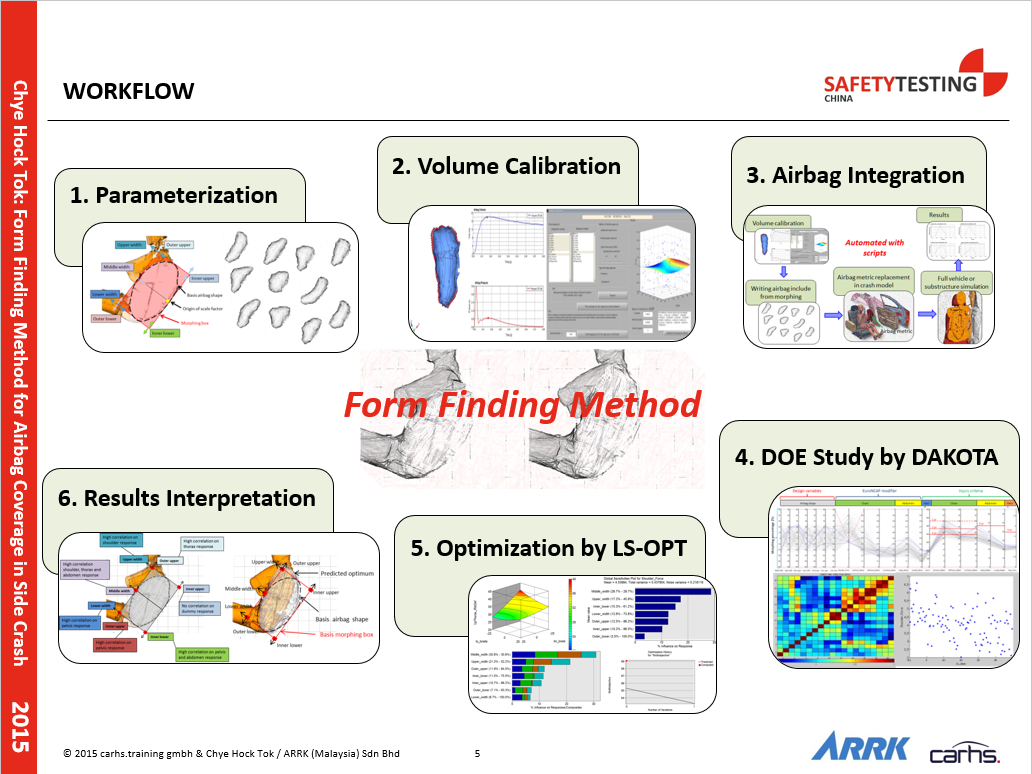

Form-finding methods

Which is the ideal shape for a side airbag under the given weight constraints? With our automated form-finding methods, it’s possible to determine the ideal coverage area for an airbag using an automated CAE process.

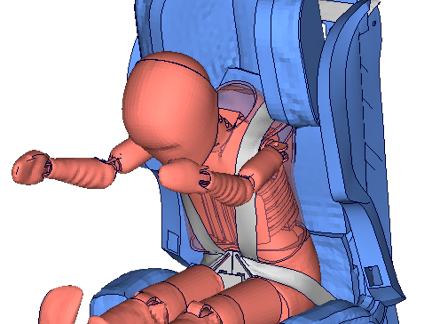

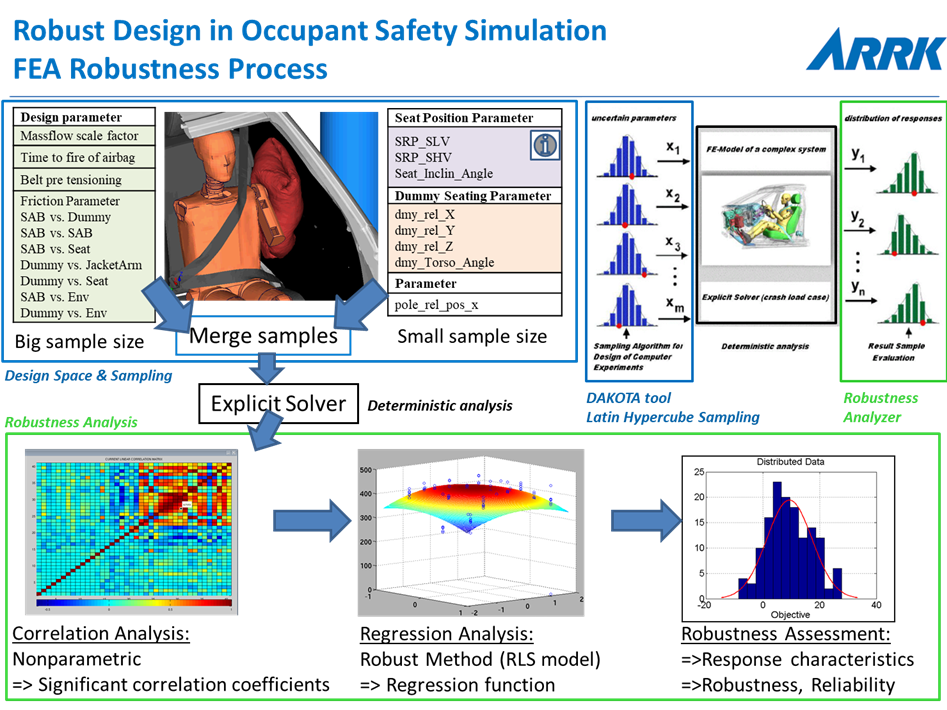

Robustness

Methods of testing robustness become relevant in relatively narrow solution spaces. If systems are already designed close to the technical limits, natural variations in starting constraints may pose the risk of systemic failure. We establish the effects of the dummy sitting position on the robustness of the crash results.

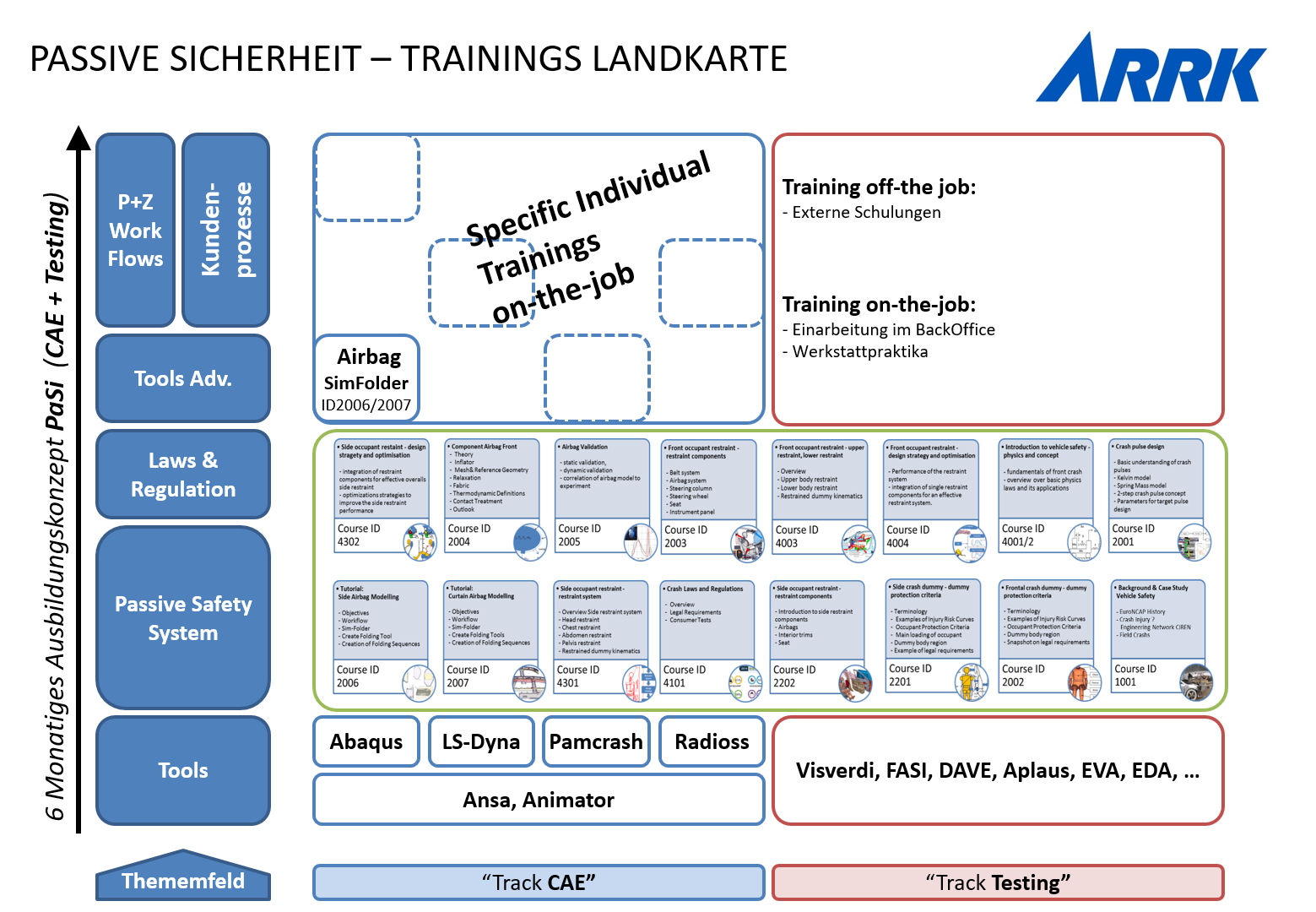

Training concept for passive vehicle safety (CAE & testing)

We see a considerable distinction in our employees’ specialist development. We train our employees, in accordance with an established concept, in all design disciplines of passive safety, current standards and requirements, and in using crash-specific tools, such as CAE Solver.

We offer this training in German, English, Chinese and Japanese worldwide.