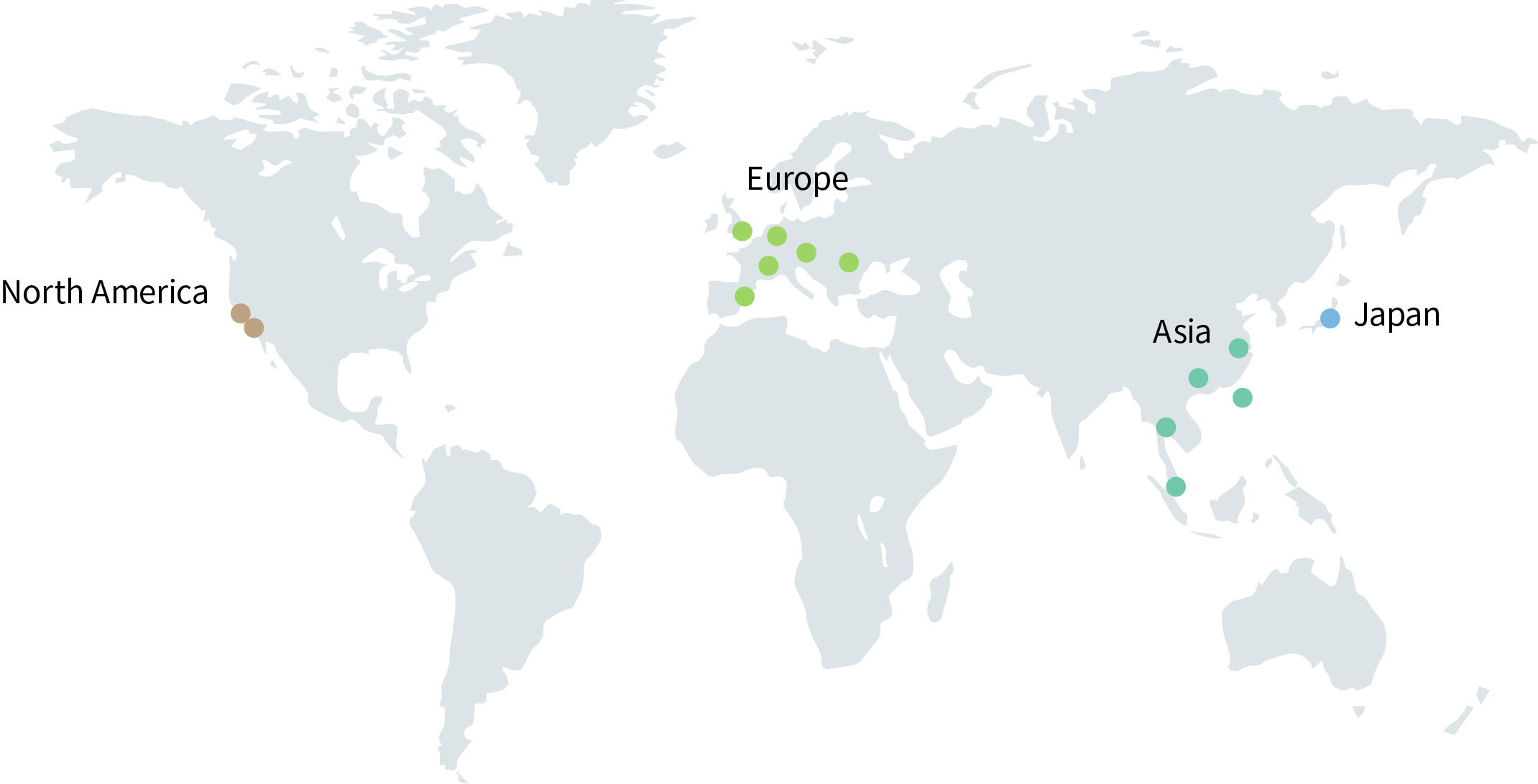

For over 70 years ARRK has supported renowned customers worldwide in the development of their products. Our many years of experience and the stellar expertise of our specialists lead to innovative and competitve products that ensure our customers' success in the marketplace. Our customers can count on innovation, dependability, and sustainability for smooth development of their products by our competences.

4660 La Jolla Village Drive Suites 100 & 200, San Diego, CA 92122

Calle Siete Sur 9057-1 Ciudad Industrial Otay, Tijuana, B.C. CP 22505

Olympus Park, Quedgeley, Gloucester, Gloucestershire, GL2 4NF, U.K.

Titaniumstraat 3, 6031 TV, Nederweert, Netherlands

Z.I. des grands Vris / 194 Allée de Champs Galère, 74540 Alby-sur-Chéran, France

Frankfurter Ring 160, 80807 Munich, Germany

Str. Fabricii de Chibrituri 13-21, cladirea ICPIAF, etajele 6 şi 7; 400254, Cluj-Napoca Romania

Bangkadi Industrial Park, 147 Moo 5, Tiwanon Road, Tambol Bangkadi, Amphur Muang, Pathumtani 12000, Thailand

Block E-10-01, Oasis Ara Damansara, Jalan PJU 1A/7A,Ara Damansara, 47301 Petaling Jaya,

No.4 Hong Ye Zhong Lu ChangAn Dongguan, Guangdong, 523856, China

Room 2602A, Central Park, Jing’an, 329 Hengfeng Rd., 200070, Shanghai, China

No.7, Ln.116, Wugong 2nd Rd., Wugu Dist., New Taipei City 248018, Taiwan

2-2-9-11F, Minami Hommachi, Chuo-ku, Osaka-Shi, Osaka 541-0054

C/Murcia No. 58B, Pol.Ind. Can Calderon 08830 Sant Boi de Llobregat, Barcelona. Spain

Olympus Park, Quedgeley, Gloucester, Gloucestershire, GL2 4NF, U.K.

Google Map

TEL:+44-1452-727700

Caldwell Road,Nuneaton, Warwickshire, CV11 4NG, U.K.

Google Map

TEL:+44-2476-580700

C/Murcia No. 58B, Pol.Ind. Can Calderon 08830 Sant Boi de Llobregat, Barcelona. Spain

Google Map

TEL:+34-936-616001

Frankfurter Ring 160, 80807 Munich, Germany

Google Map

TEL:+49-89-31857-0

Levelingstr. 1, 85049 Ingolstadt, Germany

Google Map

TEL:+49-841-88190-0

Wankelstraße 3 (STEP 5), 70563 Stuttgart, Germany

Google Map

TEL:+49-711-620412-0

Oskar-Schindler-Str. 9, 50769 Köln, Germany

Google Map

TEL:+49-221-534380-108

Alessandro-Volta-Straße 22 38440 Wolfsburg, Germany

Google Map

TEL:+49-5361-890812-100

Alemannenstr. 19, 71296 Heimsheim, Germany

Google Map

TEL:+49-7033-692630

Address:Str. Fabricii de Chibrituri 13-21, cladirea ICPIAF, etajele 6 şi 7; 400254, Cluj-Napoca Romania

Google Map

TEL:40-364-413-600

Address:Z.I. des grands Vris / 194 Allée de Champs Galère, 74540 Alby-sur-Chéran, France

Google Map

TEL:+33-4-50-68-12-39

Address:Titaniumstraat 3, 6031 TV, Nederweert, Netherlands

Google Map

TEL:+31-495-459-220

4660 La Jolla Village Drive Suites 100 & 200, San Diego, CA 92122

Google Map

TEL:+1-858-552-1587

Calle Siete Sur 9057-1 Ciudad Industrial Otay, Tijuana, B.C. CP 22505

Google Map

TEL:+52-664-607-4760

No.7, Ln.116, Wugong 2nd Rd., Wugu Dist., New Taipei City 248018, Taiwan

Google Map

TEL:+886-2-8966-7768

Room 2602A, Central Park, Jing’an, 329 Hengfeng Rd., 200070, Shanghai, China

Google Map

TEL:+86-21-6139-0170

No.4 Hong Ye Zhong Lu ChangAn Dongguan, Guangdong, 523856, China

Google Map

TEL:+86-769-8606-2100

Bangkadi Industrial Park, 147 Moo 5, Tiwanon Road, Tambol Bangkadi, Amphur Muang, Pathumtani 12000, Thailand

Google Map

TEL:+66-2-501-1170

Block E-10-01, Oasis Ara Damansara, Jalan PJU 1A/7A,Ara Damansara, 47301 Petaling Jaya, Selangor, Malaysia

Google Map

TEL:+60-3-7734-7692

Ideal Avenue 1-3-12, Medan Kampung Relau 1, 11900 Bayan Lepas, Penang.

Google Map

TEL:+60-4638-1228

18 Ah Hood Road, Hiap Hoe Building At Zhongshan Park, #08-51, Singapore 329983

Google Map

TEL:+65-6992-8052

11F, Tatsuno Minami Hommachi Building, 2-2-9 Minami Hommachi, Chuo-ku, Osaka-Shi,Osaka 541-0054

Google Map

1-7-1 Senzui, Asaka-Shi, Saitama 351-0024

Google Map

TEL:+81-48-458-5055 FAX:+81-48-458-5532

2-4-3 Kawazuracho, Tondabayashi-Shi, Osaka 584-0014

Google Map

TEL:+81-721-24-0403 FAX:+81-721-24-0455

500-30 Minamiyama, Komenokicho, Nisshin-shi, Aichi 470-0111

Google Map

TEL:0561-72-5550 FAX:0561-72-5553

1-1 Harajyuku, Hidaka-Shi, Saitama 350-1205

Google Map

TEL:+81-42-985-1656 FAX:+81-42-984-0230

770 Ipponsugi Harajuku, Hidaka-Shi, Saitama 350-1205

Google Map

2-12-8 Mukaibara, Fujiyoshida-shi, Yamanashi 403-0018

Google Map

TEL:+81-555-24-1811 FAX:+81-555-20-1080

3413-46 Tonya-Cho, Utsunomiya-Shi, Tochigi 321-0911

Google Map

TEL:+81-28-657-5225 FAX:+81-28-656-6562

Pasutoraru Asahi 301, 5-43-14, Asahicho, Atsugi-shi, Kanagawa 223-0014

Google Map

TEL 81-46-229-2088 / FAX 81-46-220-5005